In-Mold Decorations in Modern Production: A Comprehensive Guide

Wiki Article

Understanding In-Mold Decorations: Techniques, Patterns, and Best Practices for Optimum Results

In the realm of production, the art of in-mold decorations stands as a critical facet of product layout and manufacturing. As markets consistently look for ingenious methods to boost aesthetic allure and capability, understanding the intricacies of in-mold decors has actually become an important ability. From selecting the best products to including advanced design trends, the trip in the direction of achieving optimum lead to this domain name is multifaceted. By delving into the techniques, fads, and finest practices that underpin successful in-mold decor processes, businesses can unlock a world of opportunities that not only boost the aesthetic allure of their items however additionally simplify production effectiveness and reinforce consumer engagement.Material Selection

Material selection is a vital element of grasping in-mold decors, as it straight impacts the top quality and longevity of the last item. When selecting materials for in-mold decors, it is necessary to take into consideration aspects such as compatibility with the molding procedure, the preferred aesthetic result, and the ecological problems the product will certainly deal with.Furthermore, products with high warm resistance are favored for in-mold designs, particularly for products that will be exposed to raised temperatures throughout their lifecycle. By meticulously selecting the proper material for in-mold designs, manufacturers can enhance the overall quality and toughness of their items, meeting the assumptions of both end-users and clients - In-Mold Decorations.

Design Advancement

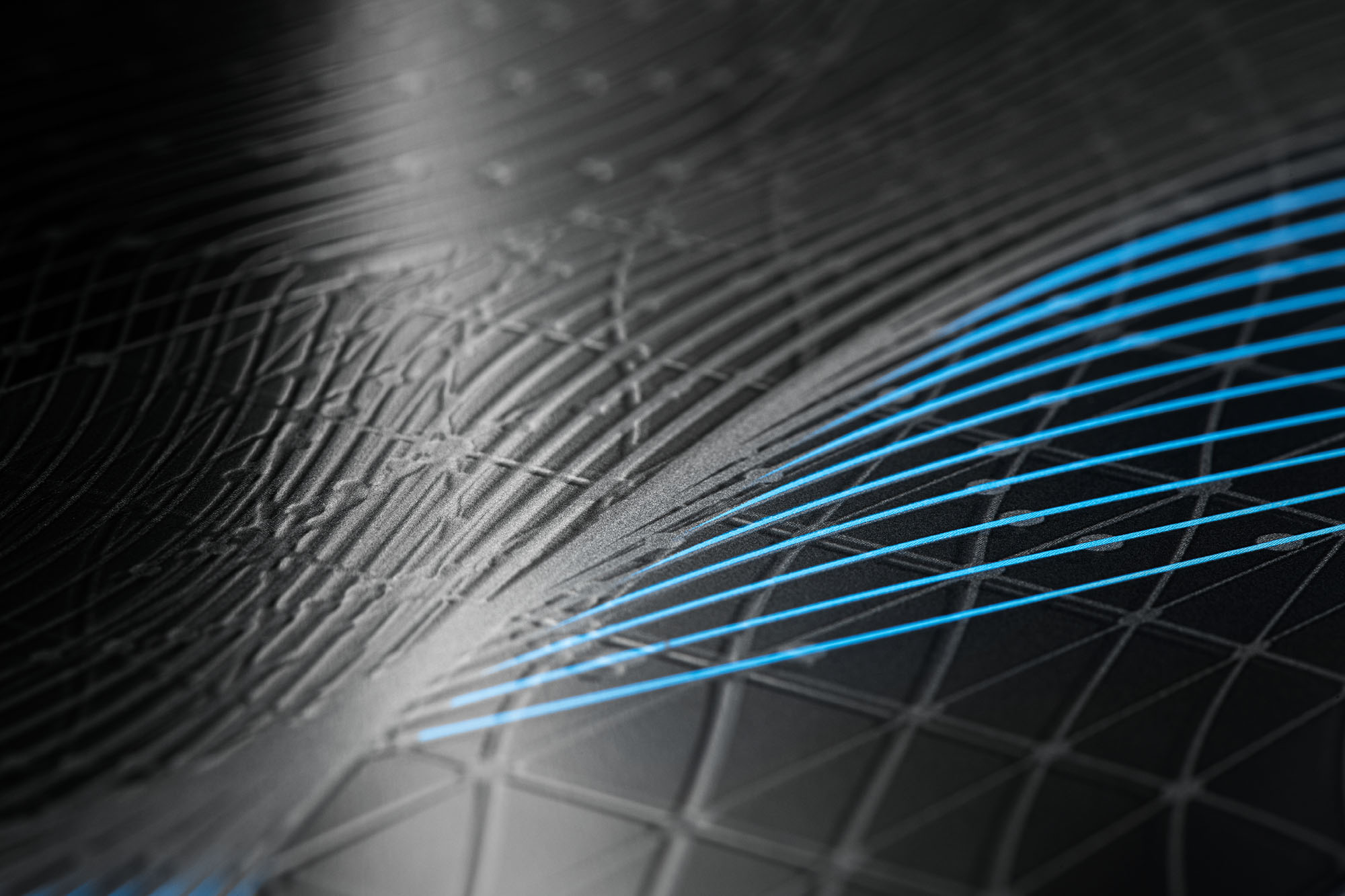

An essential consider advancing the field of in-mold decors is the constant exploration and implementation of layout advancement strategies. Layout innovation plays a crucial duty in enhancing the visual appeal, functionality, and general high quality of products made utilizing in-mold decor processes. By integrating cutting-edge layout components, makers can differentiate their products in the marketplace, bring in customers, and remain in advance of competitors.One of the crucial elements of layout advancement in in-mold decorations is the assimilation of detailed patterns, appearances, and graphics that were previously testing to achieve with standard decoration approaches. Advanced technologies such as 3D printing and digital design tools allow developers to produce facility and detailed designs that can be perfectly transferred onto shaped components. In addition, the usage of lively colors, metallic finishes, and unique impacts like gloss or matte textures can better elevate the visual allure of in-mold embellished items.

Additionally, style advancement extends beyond aesthetics to incorporate functional enhancements such as ergonomic shapes, integrated functions, and customizable elements that satisfy specific user requirements. By embracing layout innovation, producers can unlock new possibilities for imagination, customization, and product distinction in the competitive landscape of in-mold decors.

Manufacturing Performance

Effective production procedures are important for equating the ingenious styles created in the field the original source of in-mold decors into high-quality ended up items that fulfill market needs and consumer assumptions. In the realm of in-mold decors, production efficiency encompasses various crucial aspects that add to the overall success of the manufacturing process.Automation not just accelerates the production process yet also improves precision and repeatability, leading to a much more top notch and uniform end product. In general, an all natural method to manufacturing performance is vital in making the most of the potential of in-mold design techniques and achieving optimum outcomes in the competitive market landscape.

Top Quality Control Measures

What are the key techniques for ensuring strict top quality control steps in the world of in-mold designs? Quality control procedures are paramount in in-mold decor procedures to guarantee the production of remarkable and premium ended up items.Using advanced modern technologies such as computerized inspection systems can additionally improve the top quality control procedure by view website providing precise and reputable information for analysis. These systems can detect imperfections that may be missed by hands-on inspections, thus improving total product top quality and uniformity.

Normal training and growth programs for employees associated with the in-mold decoration procedure can also add to maintaining top notch requirements. By informing team on finest practices, top quality expectations, and the relevance of attention to detail, companies can promote a society of top quality awareness throughout the company.

Customer Allure

To enhance the bankability of in-mold design items, catering and understanding to customer preferences play an essential duty in determining their appeal and success. Supplying personalization choices such as individualized styles, explanation color variations, and textural elements can considerably enhance the appeal of in-mold decor items.

Conclusion

In-mold decors provide a reliable and functional means to enhance item appearances. By carefully choosing products, welcoming ingenious styles, optimizing production processes, executing high quality control steps, and focusing on consumer allure, suppliers can attain ideal outcomes. It is essential for business to continuously adapt and improve their techniques to stay competitive in the marketplace. In-Mold Decorations. Understanding in-mold designs requires a holistic approach that takes into consideration all elements of the production procedure to guarantee success.In the world of production, the art of in-mold decorations stands as a crucial element of item style and production. Design advancement plays a crucial function in improving the aesthetic appeal, capability, and total quality of products manufactured using in-mold decoration processes.One of the key elements of layout technology in in-mold decors is the integration of intricate patterns, textures, and graphics that were formerly testing to attain with conventional design methods.Effective production procedures are important for converting the cutting-edge styles created in the area of in-mold decors right into premium finished items that meet market needs and customer expectations. Using modification alternatives such as customized designs, color variations, and textural aspects can dramatically boost the allure of in-mold decor products.

Report this wiki page